أرسل لنا رسالة

Coke crusher Safety operation rules

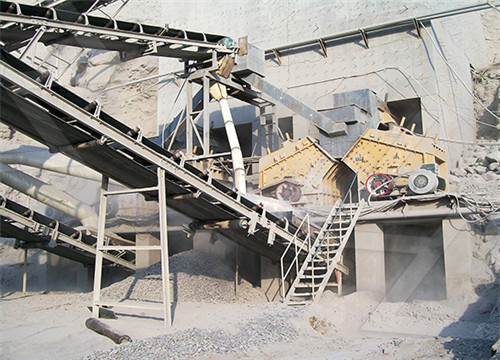

Site Safety and Safer Aggregate Crushing Operations Agg

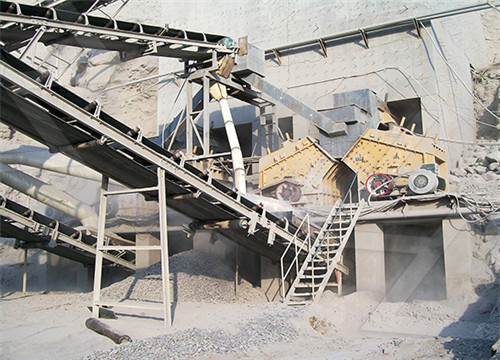

2019911 Tips for keeping a safe site include ensuring effective signage, keeping the site clean, walking the site daily, and maintaining quarry faces and haul roads. No one should ever turn a blind eye to a hazard or hazardous situation. Do not say: ‘It’s not my

HSE Quarries Safe operation and use of mobile jaw crushersCrushing and Screening Handbook AusIMMAggregates Safety Series: Small Mines Mine Safety and WhatsApp Web

Crushing and Screening Handbook AusIMM

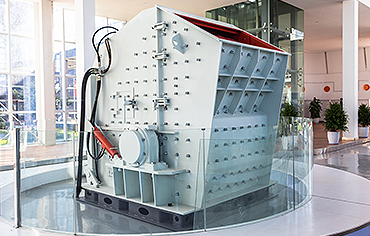

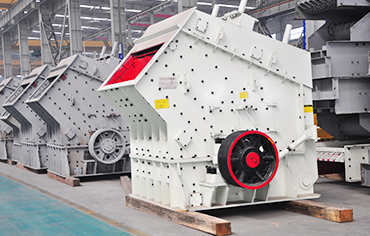

2021624 for your aggregates processing operations. Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for

: 9MB

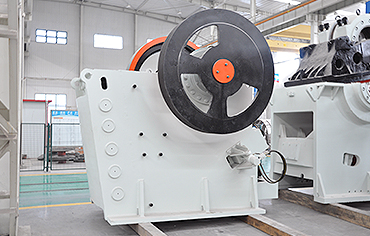

HSE Quarries Safe operation and use of mobile jaw crushers

20231012 It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not

mobile crusher risk assessment MiningQuarry Plantrisk assessment on jaw crusher MiningQuarry Plant

Coke-crusher case study Engineer Live

20221031 Keeping harmful substances out of the air Petroleum coke is a waste product resulting from the thermal cracking of crude oil. The crushers from Jülch must

COKE CRUSHING CHARACTERISTICS University of

20041222 coke producers strive to obtain a maximum yield of 3/4" x 1/8" size, or a similar size acceptable to the customer, and a minimum yield of the less valuable fines.

: 286KB

Top safety tips for working around crushing and

2020612 Working around crushing and screening equipment brings plenty of potential dangers. There are many ways that a careless employee could potentially face harm around aggregates equipment, but a few

:CrusherCrushing And Screening EquipmentCrushing Screening Services

Safety Operation Procedures of Crusher Luoyang

201934 7. Do not cut any current-carrying wires when working with electricity. 8. Before work, check whether the tool is good, and use the tool reasonably. First check the safety situation on the site before work to

An AdvancedCoke Handling Process Refining Community

2023621 Operational Safety Reliability Plot Requirement Total Investment (CAPEX) OperatingCosts(OPEX) Coke Drum Crusher Sluiceway Hydrobin Coke Water

:CrusherClosed Coke Slurry SystemCoke HandlingMicrosoft Powerpoint

(73c) The Closed Coke Slurry System AIChE

20231023 The Closed Coke Slurry System (CCSS) developed by TriPlan AG in Germany offers a reliable way to make the unloading of coke drums more efficient,

:CrusherClosed Coke Slurry System

Operating Rules Of Cone Crusher m.sbmchina

20211124 Here we introduce some proper ways to operate cone crusher. Operating Rules Of Cone Crusher. In this article, we mainly introduce the operating rules of cone

CNU Petroleum coke crusher Google Patents

The utility model provides a petroleum coke crusher which comprises an electric control system, a grate body, rails, a machine frame, a main crusher body and a travel drive system, wherein the grate body is arranged above a receiving hopper and covers a material inlet of the whole receiving hopper; the rails are arranged on the two upper sides of the grate

Top safety tips for working around crushing and

2020612 The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical

Coke crusher Safety operation rules

Coke crusher Safety operation rules [PDF] COKE CRUSHING CHARACTERISTICS University of . 20041222 coke producers strive to obtain a maximum yield of 3/4" x 1/8" size, or a similar size acceptable to the customer, and a minimum yield of the less valuable fines. Coke fines can be kept at a minimum by choosing the proper coal, or coal

HSE Quarries Safe operation and use of mobile jaw crushers

20231012 Being on the access platform during normal operation presents the following risks: Struck by objects ejected from the crusher, such as bits of stone or metal. The operation of the crusher catches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar).

8 Tips for Crusher Safety Stewart-Amos Equipment Company

20221027 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

2023710 Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30-06-2016 1. OBJECTIVE: To evolve uniform safety procedure in Operation and Maintenance of Coal Conveyors Belts for ensuring the safety in OM in Coal Handling Plants. 2. SCOPE: This procedure applies to different types of conveyors used in coal

Terrasource Industries Petroleum/Coke

Petroleum/Coke. Our crushers are installed at the refineries and at power plants that burn this fuel in fluid bed boilers. At the refineries, our equipment crushes the coke as it is cut out of the coking drums. Petroleum coke is a waste material from the refining process but has favor as a fuel. All of the major suppliers of coking technology

Top 10 Coal Companies in India List 2023 Updated

2 For more : Tobacco companies in India Coal India Limited (CIL) Coal India Limited (CIL) the state owned coal mining corporate came into being in November 1975. With a modest production of 79 Million Tonnes (MTs) at the year of its inception CIL today is the single largest coal producer in the world and one of the largest corporate employer

An AdvancedCoke Handling Process Refining Community

2023621 Operational Safety Reliability Plot Requirement Total Investment (CAPEX) OperatingCosts(OPEX) Coke Drum Crusher Sluiceway Hydrobin Coke Water Clarification System Coke Fines Chute Closed Coke Slurry System Enhances Coking Operations-Vermiere-TriPlan-DCU-Mumbai-2016.pptx

Conveyor Safety [PPT Powerpoint] vdocument

2015516 1. Conveyor Safety 10-3-07 Frank J. Loeffler Jr. Loeffler Engineering Group 2. STANDARDS OSHA 29 CFR .555 CEMA Belt Conveyor Handbook, Safety Labels 201 &

Crushing Products Size and Shape -What to

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or

Site Safety and Safer Aggregate Crushing Operations Agg

2019911 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and pressure are all monitored. Safety is something that can be carried out and planned for daily, monthly and yearly. Every day, operators

U.S. DEPARTMENT OF LABOR Occupational Safety and

2020219 This pdf document provides guidance on the hazards and control measures of combustible dust in various industries, based on the U.S. Department of Labor Occupational Safety and Health Administration (OSHA) standards and regulations. It covers topics such as dust explosion scenarios, hazard assessment, engineering controls,

SAFETY GUIDELINES FOR IRONSTEEL SECTOR

202336 Permit to Work (OperationMaintenance). 3.3 Safety Precautions during maintenance work in a Conveyor Belt 3.3.1 Conveyor Drive i. Stop the conveyor belt, when it is empty. Never stop the belt in load. ii. Ensure permit to work system is followed before starting of work as per SG-04: Safety Guideline for Permit to Work (Operation

Jaw Crusher an overview ScienceDirect Topics

The relationship between the frequency of operation and capacity of the jaw crusher can be seen in Figure 4.5. This figure is plotted for values of L T = 0.228 m, W = 1.2 m, L MIN = 0.10 m, R = 10 For soft materials, such as coal and coke, K = 0.5. For harder materials, such as quartz and granite, K = 1.

Roll crushers PPT SlideShare

2015423 8.DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or

BBS and CD between bearings single stage pumps Sulzer

The double suction impeller provides reduced NPSH3 for tough services in refineries and other critical applications. The CD can be custom engineered for high pressure, special hydraulics and special nozzle locations. Main design features. Centerline supported casing with top / top nozzles; side / side nozzles optional. Thermal expansion features.

Site safety and safer aggregate crushing operations Quarry

2020417 There are many key priorities to consider when ensuring overall site safety and safer crushing operations. Safety requires proactive intervention to prevent workplace accidents. Each company or site should have clear safety guidelines outlining best practices for the entire site, especially for crushers. Before even stepping on site to work

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Crushing and Screening Handbook AusIMM

2021624 for your aggregates processing operations. Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for

HSE Quarries Safe operation and use of mobile jaw crushers

20231012 It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers. This guidance cannot cover every risk and is not

Coke-crusher case study Engineer Live

20221031 Keeping harmful substances out of the air Petroleum coke is a waste product resulting from the thermal cracking of crude oil. The crushers from Jülch must

COKE CRUSHING CHARACTERISTICS University of

20041222 coke producers strive to obtain a maximum yield of 3/4" x 1/8" size, or a similar size acceptable to the customer, and a minimum yield of the less valuable fines.

Top safety tips for working around crushing and

2020612 Working around crushing and screening equipment brings plenty of potential dangers. There are many ways that a careless employee could potentially face harm around aggregates equipment, but a few

Safety Operation Procedures of Crusher Luoyang

201934 7. Do not cut any current-carrying wires when working with electricity. 8. Before work, check whether the tool is good, and use the tool reasonably. First check the safety situation on the site before work to

An AdvancedCoke Handling Process Refining Community

2023621 Operational Safety Reliability Plot Requirement Total Investment (CAPEX) OperatingCosts(OPEX) Coke Drum Crusher Sluiceway Hydrobin Coke Water

(73c) The Closed Coke Slurry System AIChE

20231023 The Closed Coke Slurry System (CCSS) developed by TriPlan AG in Germany offers a reliable way to make the unloading of coke drums more efficient,

Operating Rules Of Cone Crusher m.sbmchina

20211124 Here we introduce some proper ways to operate cone crusher. Operating Rules Of Cone Crusher. In this article, we mainly introduce the operating rules of cone

CNU Petroleum coke crusher Google Patents

The utility model provides a petroleum coke crusher which comprises an electric control system, a grate body, rails, a machine frame, a main crusher body and a travel drive system, wherein the grate body is arranged above a receiving hopper and covers a material inlet of the whole receiving hopper; the rails are arranged on the two upper sides of the grate

Top safety tips for working around crushing and

2020612 The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical

Coke crusher Safety operation rules

Coke crusher Safety operation rules [PDF] COKE CRUSHING CHARACTERISTICS University of . 20041222 coke producers strive to obtain a maximum yield of 3/4" x 1/8" size, or a similar size acceptable to the customer, and a minimum yield of the less valuable fines. Coke fines can be kept at a minimum by choosing the proper coal, or coal

HSE Quarries Safe operation and use of mobile jaw crushers

20231012 Being on the access platform during normal operation presents the following risks: Struck by objects ejected from the crusher, such as bits of stone or metal. The operation of the crusher catches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar).

8 Tips for Crusher Safety Stewart-Amos Equipment Company

20221027 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

2023710 Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30-06-2016 1. OBJECTIVE: To evolve uniform safety procedure in Operation and Maintenance of Coal Conveyors Belts for ensuring the safety in OM in Coal Handling Plants. 2. SCOPE: This procedure applies to different types of conveyors used in coal

Terrasource Industries Petroleum/Coke

Petroleum/Coke. Our crushers are installed at the refineries and at power plants that burn this fuel in fluid bed boilers. At the refineries, our equipment crushes the coke as it is cut out of the coking drums. Petroleum coke is a waste material from the refining process but has favor as a fuel. All of the major suppliers of coking technology

Top 10 Coal Companies in India List 2023 Updated

2 For more : Tobacco companies in India Coal India Limited (CIL) Coal India Limited (CIL) the state owned coal mining corporate came into being in November 1975. With a modest production of 79 Million Tonnes (MTs) at the year of its inception CIL today is the single largest coal producer in the world and one of the largest corporate employer

An AdvancedCoke Handling Process Refining Community

2023621 Operational Safety Reliability Plot Requirement Total Investment (CAPEX) OperatingCosts(OPEX) Coke Drum Crusher Sluiceway Hydrobin Coke Water Clarification System Coke Fines Chute Closed Coke Slurry System Enhances Coking Operations-Vermiere-TriPlan-DCU-Mumbai-2016.pptx

Conveyor Safety [PPT Powerpoint] vdocument

2015516 1. Conveyor Safety 10-3-07 Frank J. Loeffler Jr. Loeffler Engineering Group 2. STANDARDS OSHA 29 CFR .555 CEMA Belt Conveyor Handbook, Safety Labels 201 &

Crushing Products Size and Shape -What to

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or

Site Safety and Safer Aggregate Crushing Operations Agg

2019911 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and pressure are all monitored. Safety is something that can be carried out and planned for daily, monthly and yearly. Every day, operators

U.S. DEPARTMENT OF LABOR Occupational Safety and

2020219 This pdf document provides guidance on the hazards and control measures of combustible dust in various industries, based on the U.S. Department of Labor Occupational Safety and Health Administration (OSHA) standards and regulations. It covers topics such as dust explosion scenarios, hazard assessment, engineering controls,

SAFETY GUIDELINES FOR IRONSTEEL SECTOR

202336 Permit to Work (OperationMaintenance). 3.3 Safety Precautions during maintenance work in a Conveyor Belt 3.3.1 Conveyor Drive i. Stop the conveyor belt, when it is empty. Never stop the belt in load. ii. Ensure permit to work system is followed before starting of work as per SG-04: Safety Guideline for Permit to Work (Operation

Jaw Crusher an overview ScienceDirect Topics

The relationship between the frequency of operation and capacity of the jaw crusher can be seen in Figure 4.5. This figure is plotted for values of L T = 0.228 m, W = 1.2 m, L MIN = 0.10 m, R = 10 For soft materials, such as coal and coke, K = 0.5. For harder materials, such as quartz and granite, K = 1.

Roll crushers PPT SlideShare

2015423 8.DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or

BBS and CD between bearings single stage pumps Sulzer

The double suction impeller provides reduced NPSH3 for tough services in refineries and other critical applications. The CD can be custom engineered for high pressure, special hydraulics and special nozzle locations. Main design features. Centerline supported casing with top / top nozzles; side / side nozzles optional. Thermal expansion features.

Site safety and safer aggregate crushing operations Quarry

2020417 There are many key priorities to consider when ensuring overall site safety and safer crushing operations. Safety requires proactive intervention to prevent workplace accidents. Each company or site should have clear safety guidelines outlining best practices for the entire site, especially for crushers. Before even stepping on site to work

A review of modeling and control strategies for cone crushers

2021815 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other