أرسل لنا رسالة

crusher size distribution of rock types

The effect of rock crusher and rock type on the aggregate shape

Request PDF On Jan 10, 2020, Mojtaba Kamani and others published The effect of rock crusher and rock type on the aggregate shape Find, read and cite all the research you

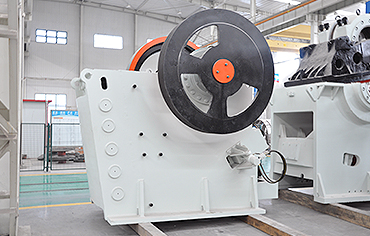

Influence of jaw crusher parameters on the quality of

202061 In each test, a minimum of 1500 kg of blasted rock was crushed. Depending on the feed gradation and the setting of the crusher, the amount of material crushed

Influence of some rock strength properties on jaw crusher

201031 Jaw Crusher is used for crushing rock material in mines and quarries. It provides the latest technology in heavy duty crusher design that delivers high pro-

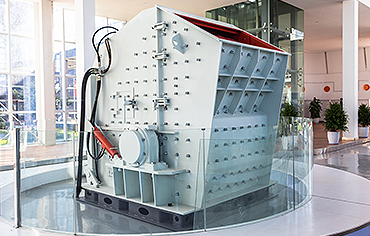

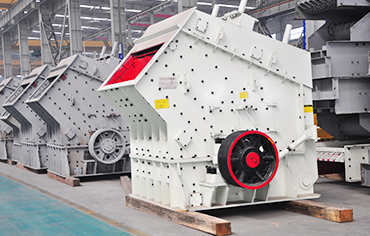

The effect of rock crusher and rock type on the aggregate

2020110 Seven samples which have three rock types, i.e., limestone, marble, and tuff, were crushed by jaw crusher (JC) and horizontal shaft impact (HSI) crusher.

A review of modeling and control strategies for cone crushers

2021815 Bearman et al. (1991) performed pilot-plant scale experiments involving a laboratory scale cone crusher to understand and predict the following two operating

(PDF) An experimental investigation on rock

2019418 Allen Howland. PDF This study covers the investigation of rock crushability using laboratory-scale cone and jaw crushers for five types of hardrocks. For this Find, read and cite all the

Minerals Free Full-Text Image Process of Rock

202177 The tested rock images are generated from a laboratory rock sample that is taken from cone crusher product with sizes ranging from 0 to 22.4 mm. The sample was sieved to obtain its actual distribution for

Concrete aggregates properties crushed by jaw and

201911 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced 60%

Evaluation of blast fragmentation effects on jaw crusher

2021921 1 Citations Metrics Abstract The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance

Gyratory and Cone Crusher ScienceDirect

201611 Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of

The effect of rock crusher and rock type on the aggregate shape

2020110 The crushing mechanism and rock type are two main factors that determine aggregate shape properties [19]. Therefore, all rock samples were crushed at the laboratory jaw crusher at the same

Evaluation of blast efficiency in aggregate quarries: facts and

2021313 X o represents the size of fragments that the primary crusher and other materials handling equipment cannot = work index for the specific rock type, kwh/ton; P: = average size of the in-situ block (m); (2009) Measurement of size distribution of blasted rock using digital image processing. J King Abdulaziz Univ Sci 20:81–93. https

Jaw Crusher ScienceDirect

201611 Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, (Metso) and others. The Metso crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors. Table 4.1.

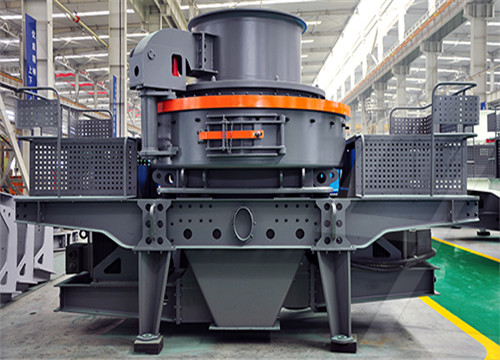

Cone Crusher an overview ScienceDirect Topics

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

Breakage process of mineral processing comminution

202091 However, in mineral processing, it is not common to reach this low level of rate. For instance, Evertsson introduced cone crushers as a compressing crusher in which the rock is broken by squeezing between two surfaces [33]. He calculated the working velocity in a specific type of cone crusher at choke-level from 0.5 to 1 m/s.

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022123 The various mill types are best suited to different ranges of feed size and product size distributions. 3.6 Comparison of Grinding Circuit Options [ 4 ] The following is intended as a general comparison of the various circuits with respect to their optimum ranges of application.

Blast Optimization and Ore Fragmentation Modeling 911

2018919 In this study, five different size-distributions or degrees of fragmentation will be studied; with. k50 = 0.05, 0.1, 0.2, 0.3 or 0.4 meter. The size-distributions can be further described by formulas, developed by the Swedish Blasting Research Foundation, (SveDeFo) where; k50 = average size of blasted rock V = spacing, meters E = Hole

Minerals Free Full-Text A Mine-to-Crusher Model to

2022818 The productivity of drilling and blasting operations can be measured by the particle size distribution of rock fragments resulting from blasting . The particle size distribution can be optimized by changing the blast design parameters, for example, the blasthole diameter [ 23 ], spacing, burden, bench height [ 19 ], stemming and specific

Practical Measurement of Size Distribution of Blasted Rocks

2020629 As a result of the measurement of particle size distribution in the pile which is stated to have a particle size between 3 and 4 inches (76.2–101.6 mm), the sieve opening (D80) through which 80% of the particles passed was measured as 151 mm and the sieve opening (D50) through which 50% passed was measured as 106 mm.

Cone crusher modelling and simulation using DEM

201611 The resulting particle size distributions for the experiments at 34 mm CSS and 50 mm CSS as well as the incoming feed can be seen in Fig. 2. Download : Download high-res image (246KB) Download : Download full-size image; Fig. 2. Particle size distributions from the crushing experiments for close side setting 34 mm and 50 mm and

Applied Sciences Free Full-Text Prediction of

2016123 Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner

Minerals Free Full-Text A Mine-to-Crusher

2022818 The productivity of drilling and blasting operations can be measured by the particle size distribution of rock fragments resulting from blasting . The particle size distribution can be optimized by changing the

(PDF) SIZE REDUCTION BY CRUSHING METHODS

201734 A crusher is a machine designed to reduce larg e rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more

Crushing Products Size and Shape -What to Expect 911

2016226 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

A method of blasted rock image segmentation based on

202253 Blasting is widely used in mining and civil engineering due to its economy and efficiency 1,2,3,4,5.As an important technical indicator of blasting effectiveness, blasted block size distribution

Determining the fragmented rock size distribution using

2019115 The results obtained showed that the most improvements in the estimation of fragmented rock size distribution were achieved, using Fourier transform, Gabor, and Fourier-wavelet methods with the value of 67%, 57%, and 48%, respectively. Also, the estimation of fragmented rock size distributions has higher MRE in fine to medium

(PDF) Modelling the crushing-sizing procedure of

2006109 Abstract and Figures. In the present stone we propose empirical models for the description of the particle size-distributions of industrial gyratory-crusher products. For the development of the

Equipment Sizing: Crusher or Grinding Mill 911 Metallurgist

201678 By referring to equipment manufacturer’s bulletin on crushers, Fig. 1, a crusher producing 80% passing 3/4″ requires a close side setting of approximately 5/8″. Since the selected crusher capacity must be in excess of 143 tons per hour, the next higher figure (159) is chosen. The 159 indicates a 548 crusher size with 1″ eccentric throw.