أرسل لنا رسالة

illustration cone rock crushers fuel for life llc

Evaluation of size reduction process for rock aggregates in cone

Mineralogical Characterization of The RocksPhysico-Mechanical and Aggregate Properties of The RocksCrushability Tests

The crushability tests are based on the fragmentation and comminution rate of rock aggregates occurred in a laboratory–scale cone crusher. The size and feeding mass of rock aggregates for the crushability tests were adopted from Dahl et al. (2012). In this context, rock aggregates with a particle size range of 11.2–16 mm were prepared for each rock...

Applied Sciences Free Full-Text Prediction of

2016123 Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner

Raptor® Cone Crushers for Mining and Aggregate

2023131 Raptor® Cone Crushers for Mining and Aggregate

Cone crusher modelling and simulation using DEM

201611 A DEM modelling framework for simulation of cone crushers is proposed. • Rock material model based on bonded particle model and calibrated against breakage

New developments in cone crusher performance optimization

200961 This stone shall review Metso Minerals’ current 3D Discrete Element Method (DEM) modeling techniques, developed to allow a detailed study of the

Modelling of flow in cone crushers ScienceDirect

1999121 Modelling of flow in cone crushers. The possibility to simulate and predict cone crusher performance is of great interest for the development of crushers as well as

Forces in a Cone Crusher SpringerLink

2019321 Configuration of basic types of cone crushers: (a, b) for coarse crushing; (c) for medium crushing; (d) for fine crushing; (1) immobile cone; (2) mobile cone; (3)

An Improved Capacity Model of the Cone

2022211 An improved capacity model of the cone crushers based on the motion characteristics of particles considering the influence of the spatial compound motion of the mantle was established by analyzing the

Cone crushers for demanding crushing needs Metso

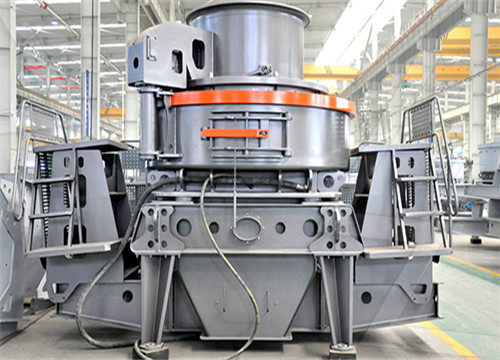

Features Cone crushers are popular rock crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in secondary,

crusher/sbm ft cs cone crushers for sale india.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

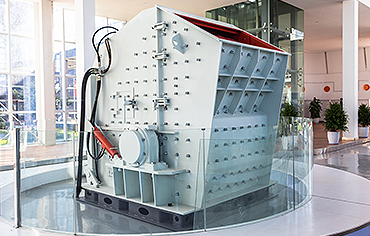

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing

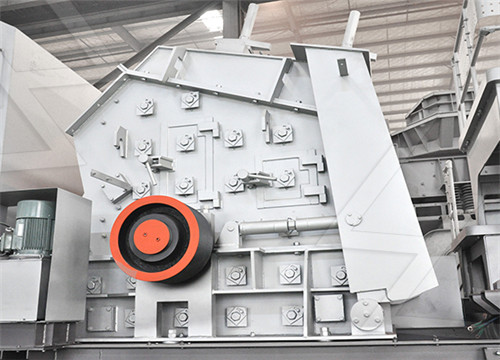

Crushing 101 Different types of crushers for

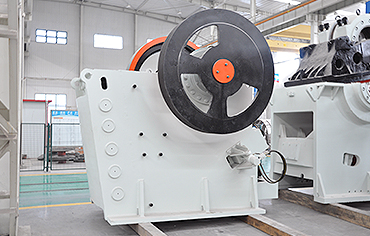

20201217 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes

Rock Crushing Rule of Thumb 911 Metallurgist

20151216 For most applications, 6:1 is the maximum practical reduction factor (ratio) for a cone crusher, but 5:1 represents better design practice. Source: Jack de la Vergne; Corrugated liner plates designed for jaw crushers (to avoid a slabby product) result in shortening liner life by up to two-thirds and they are more prone to plugging than

Crushers All crusher types for your reduction needs Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

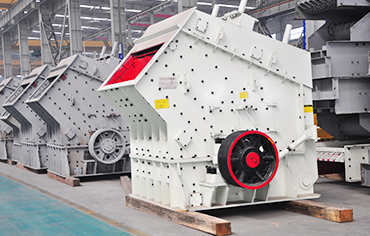

Crushing Equipment for Sale and Rent ing

The range includes both horizontal and vertical impact crushers. Models include the Trakpactor 260 and 260SR,Trakpactor 320 and 320SR, and Trakpaktor 550. Please call (800) 231-5005 with specific questions

Cone Crushers Astec

2 Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market.

Applied Sciences Free Full-Text Prediction of Cone Crusher

2016123 Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences the hydraulic pressure, power draw and liner wear. In order to dynamically analyze and calculate cone crusher performance along with liner wear, a series of experiments are performed

sbm/sbm rock crusher hire rates sydney.md at main GitHub

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Roll Crushers ScienceDirect

201611 The present trend is to replace secondary cone crushers by HPGR. The work at Polysius [3] and described by Friedrich and Baum [4], and Otte [5] indicates considerable metallurgical advantage in the extraction of minerals such as gold and copper by the use of high pressure grinding rolls. In this chapter, these two types of roll crushers

Small Short Head Cone Crusher 911 Metallurgist

2 The 911MPEPYB600 is a small (24") diameter cone crusher is perfect for fine, secondary crushing in small operations. Ideal to re-crush rock discharging from a primary jaw crusher. Feed this short head cone

Gyratory and Cone Crusher ScienceDirect

201611 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs. Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 5.1).The breaking head is fixed to a central spindle, which

The pros and cons of cone crusher applications Quarry

2021416 CONE CRUSHER TYPES. Cone crushers can be categorised into three main design types. With floating bowl and screw bowl cone crushers the upper frame raises to open CSS or relieve crushing pressure. The third type the spider-bearing cone crushers incorporate a shaft supported by a hydraulic piston which controls CSS and crushing

Primary Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. Abstract. Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to acceptable sizes. Descriptions of secondary and tertiary cone crushers that usually follow gyratory

Cone Crusher 1000 Maxtrak

20231029 The high performance ® 1000 Maxtrak portable rock crusher has been designed for direct feed applications without pre-screening on clean rock. At the heart of the Maxtrak is the Automax cone crusher with hydraulic setting, tramp release, and unblocking system. Its unique crushing action provides excellent capacity, high reduction

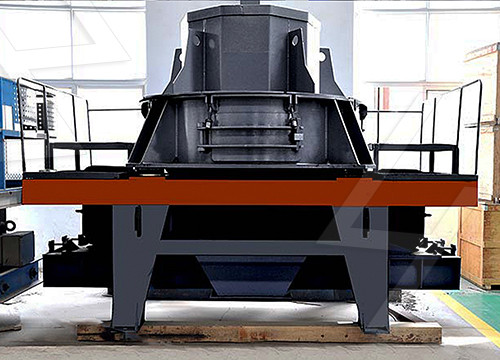

Aggregates Industry uses Industrial Diesel Generators For

Cone Crusher Includes compound cone, spring cone, hydraulic cone and gyratory crushers. A hardened cone compresses rock against a hardened surface. Used in sand and gravel production. Material can be dry to slightly wet. Shaft Impactors Can be vertical or horizontal in design. These crushers use impact rather than pressure to crush the

Fuel economy drives contractor’s mobile plant purchase

20201130 A key benefit of the diesel-electric machines that the producer will appreciate as the project goes on is the fuel economy when compared to competitors. The MC120PRO is currently averaging around 17 to 18 litres per hour (lt/hr) during production, the MCO11PRO around 23 to 25 lt/hr, and the MS952 around 12 to 13 lt/hr.